-

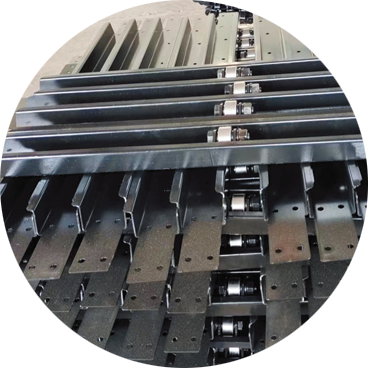

High strength anti-corrosion chain

The special processing chain is not only highly anticorrosive, but also made of removable single end replaceable type, which greatly reduces the maintenance cost in the future.

-

Special anti-corrosion electroplated cross link wrench

The high-strength steel is formed by one-time stamping and treated with special anti-corrosion process, which has a clean and beautiful appearance, super anti-corrosion and strong wear resistance.

-

German anticorrosive paint spraying frame

The vehicle frame is sprayed with German anti-corrosion paint to prevent rust during the use of the frame.

-

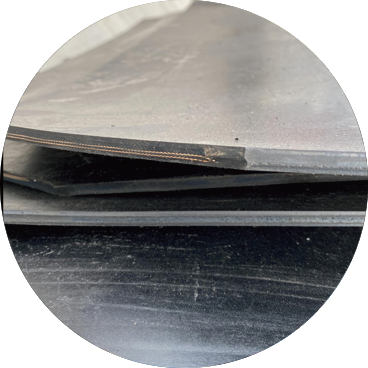

National standard oil resistant, acid and alkali resistant, high temperature resistant conveyor belt

The conveyor belt rubber is designed as a three-layer superimposed structure, with high overall strength, strong wear resistance and convenient maintenance.

-

Digital HD camera

Compared with the traditional analog camera, it has great advantages in anti electromagnetic interference, picture definition and resolution.

-

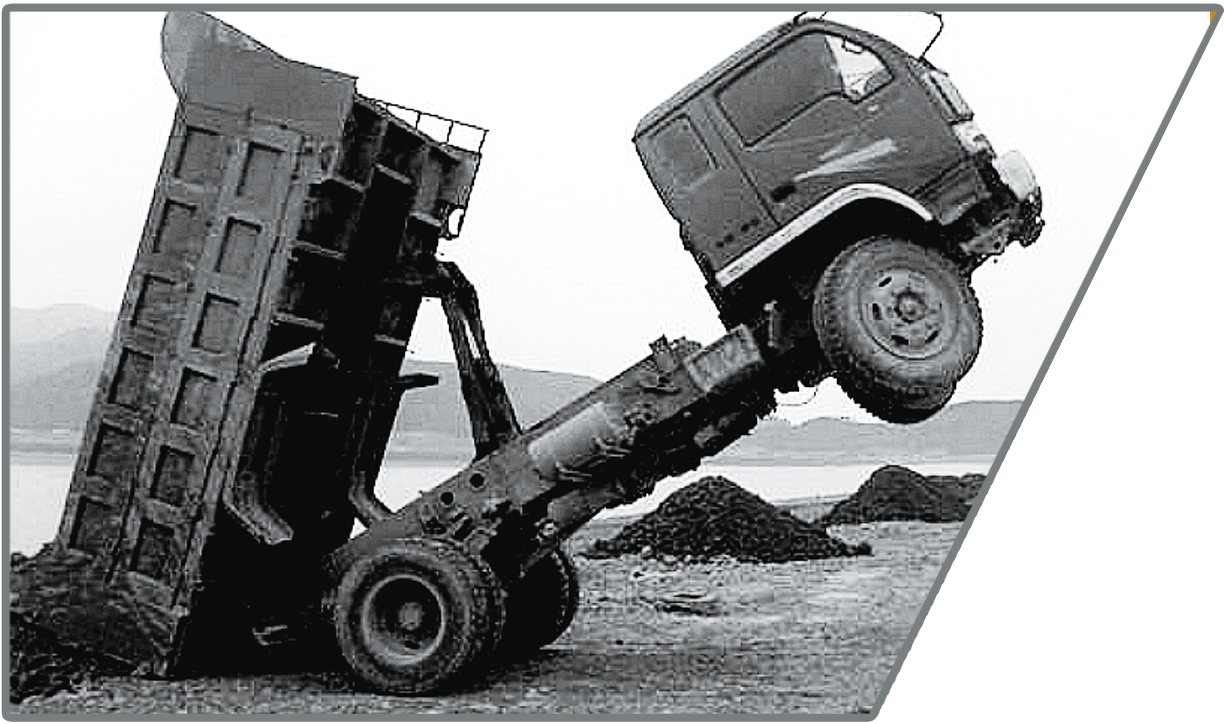

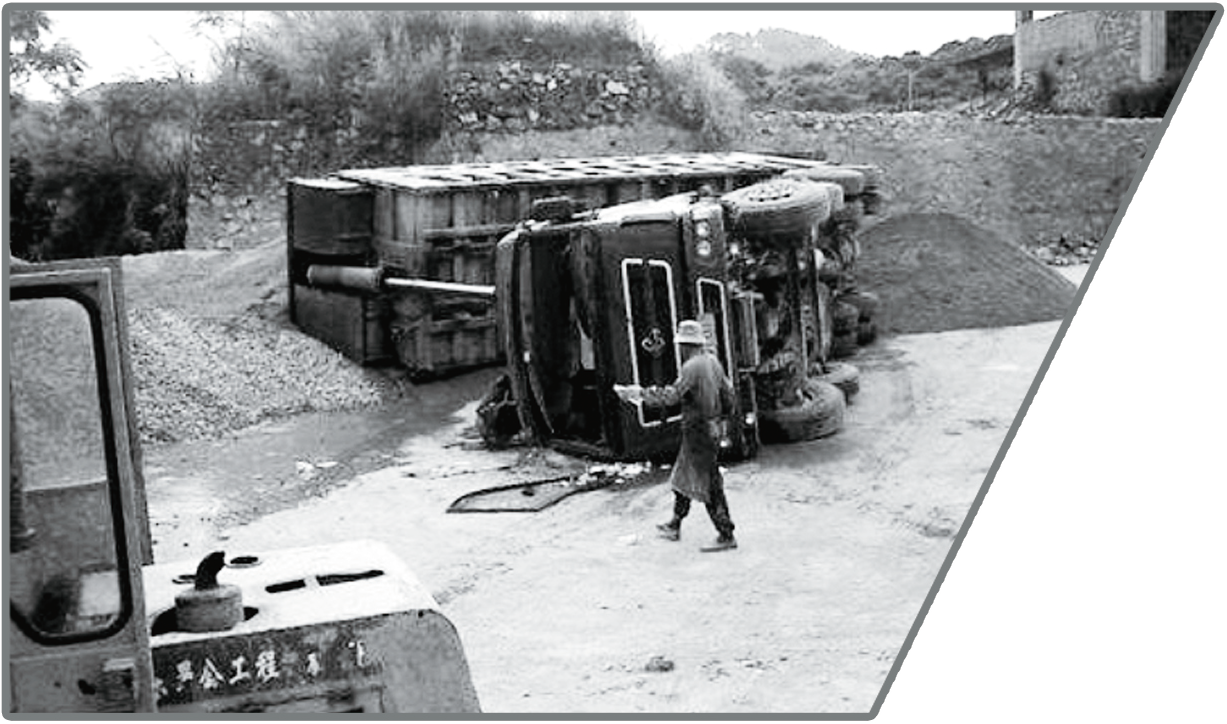

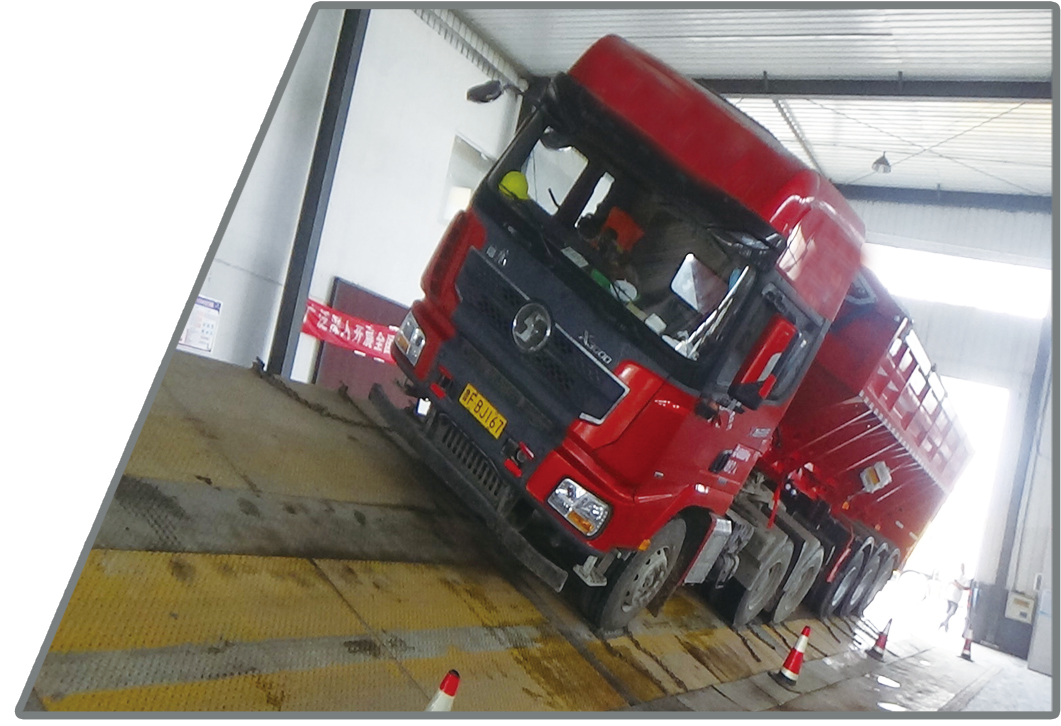

Hydraulic automatic opening rear door

The whole unloading process, from the opening of the back door to the completion of unloading, does not require any human participation to ensure the safety of the staff.

-

Folding hydraulic automatic top cover

Full hydraulic remote control operation saves time and effort. Safe and environmental protection, fast and convenient.

-

Remote control and manual dual operation system

It has high sensitivity, long remote control distance, strong anti-interference ability, intelligent logic key design, simple operation, easy to use, and convenient maintenance.